In the industrial sector, the demand for reliable and efficient control systems is ever-increasing. Among these systems, explosion-proof electric butterfly valves play a crucial role, especially in industries dealing with volatile substances. The need for safety and reliability has led to the emergence of specialized manufacturers focused on producing high-quality explosion-proof electric butterfly valves. This article explores the importance of these valves, the features that define a leading manufacturer, and the overall impact of such manufacturers on the industry.

Understanding Explosion-Proof Electric Butterfly Valves

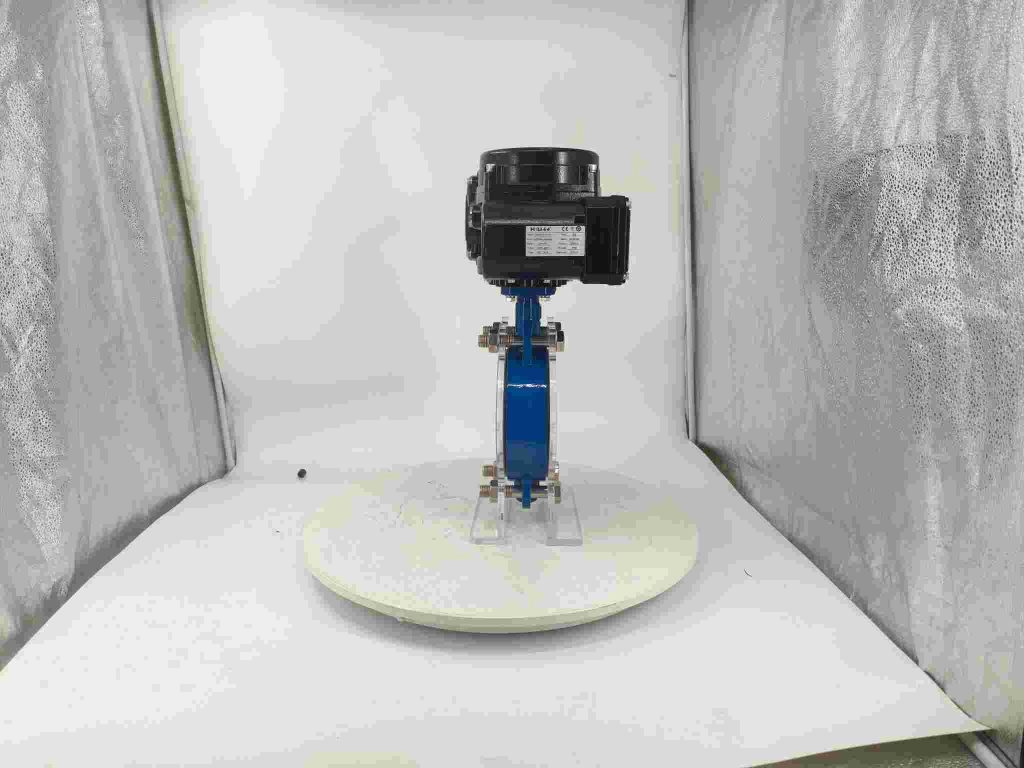

An explosion-proof electric butterfly valve is a device used to regulate the flow of liquids or gases in a pipeline. What sets it apart from standard butterfly valves is its construction, designed to operate safely in potentially explosive environments. These valves are commonly found in sectors such as oil and gas, chemical manufacturing, and wastewater treatment, where the presence of flammable materials poses a significant risk. The core components of an explosion-proof electric butterfly valve include a valve body, a disc, an actuator, and a control system. The actuator is typically electric, allowing for remote operation, which enhances safety and convenience. The explosion-proof design ensures that any sparks or heat generated by the actuator do not ignite surrounding flammable materials, thereby preventing catastrophic failures.

Leave a Reply

You must be logged in to post a comment.