A Flow Control Solenoid Valve is a pivotal component in modern fluid control systems, offering efficient regulation of flow rate in various applications, particularly in hydraulic and pneumatic systems. These valves are designed to automatically control the flow of fluids, providing a level of precision and efficiency that manual control mechanisms cannot achieve. This article explores the working principles, types, applications, and advantages of flow control solenoid valves, highlighting their significance in automation and modern machinery.

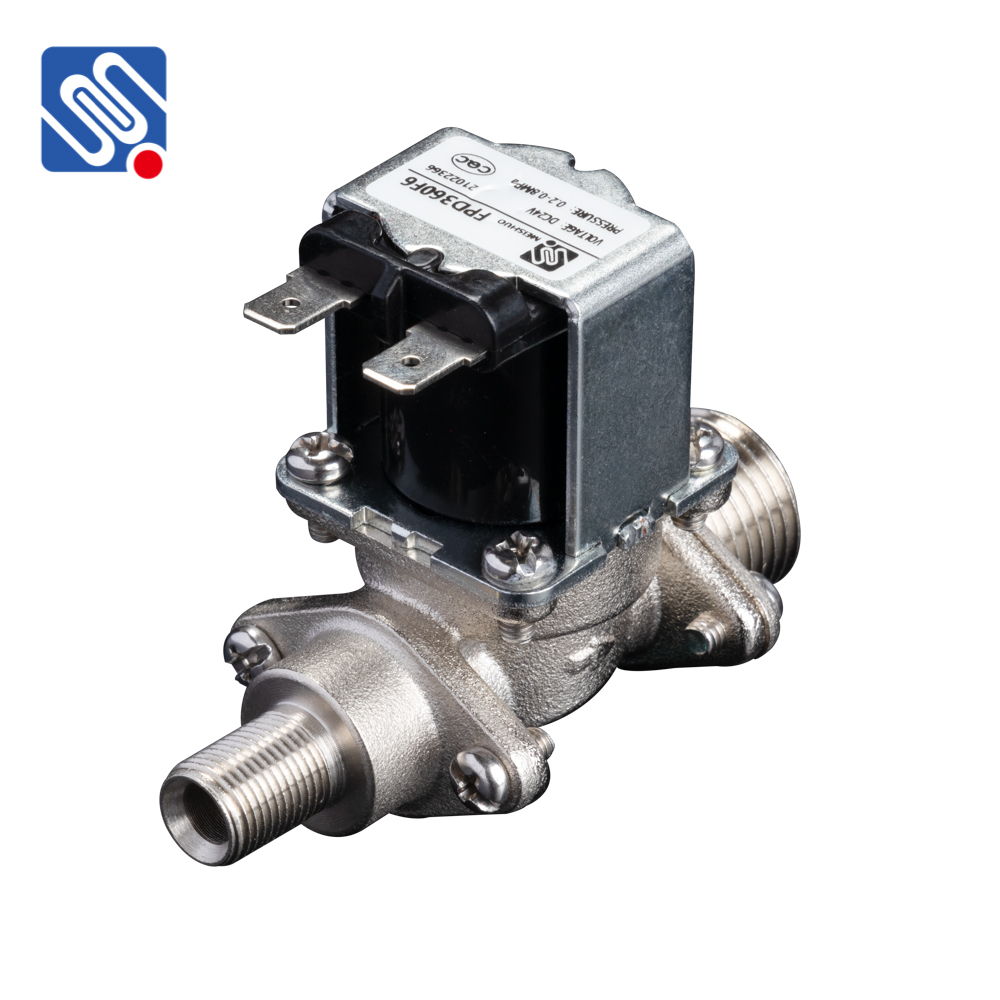

What is a Flow Control Solenoid Valve? A Flow Control Solenoid Valve is an electromechanical device that uses an electromagnetic coil to regulate the flow of fluids, typically liquid or gas, through a system. The valve works by converting electrical energy into mechanical movement, which adjusts the valve’s orifice, thereby controlling the flow rate. Solenoid valves are commonly used in systems where precise flow control is essential, such as hydraulic circuits, pneumatic systems, automotive applications, and manufacturing automation. Principle of Operation The operation of a flow control solenoid valve is relatively straightforward but highly effective. The valve is powered by an electric signal that activates a solenoid. When the solenoid is energized, it generates a magnetic field, which moves the valve’s internal components, typically a plunger or armature, either opening or closing the flow path. The movement of these components adjusts the size of the valve’s orifice, thus controlling the flow of fluid passing through the valve.

Leave a Reply